钎焊板式换热器

Contact Now

- TEL:+86-133 9515 7738

- FAX:

- Email:sales@greenheatexchanger.com

Brazed Plate Heat Exchanger features

The stainless steel plates are brazed together, then no need for gasket and frames.the contact points to help hold the plates together,also can take high pressure.the brazing material function is sealing the stainless steel package.GHE’s brazed heat exchangers are brazed at all contact points,to make sure best heat transfer efficiency and pressure resistance.the advance of brazed plate heat exchanger is compact size and light weight,also can take high preesure up to 4.5Mpa.GHE offers a flexible customer-made design to meet customer-specific requirements then to ensure the most cost-efficient solution for customers’ heat transfer duties.

Brazed Plate Heat Exchanger Material

The BPHE(Brazed Plate Heat Exchanger) main components are stainless steel corrugated plates and copper sheet,the stainless steel plates are brazed together by brazing material (Copper or Nickel)in Vacuum Furnace.Copper brazed heat exchanger can be sued for numerous of applications.however ,for food or application involving aggressive fluids,Nickel brazed units are recommend .

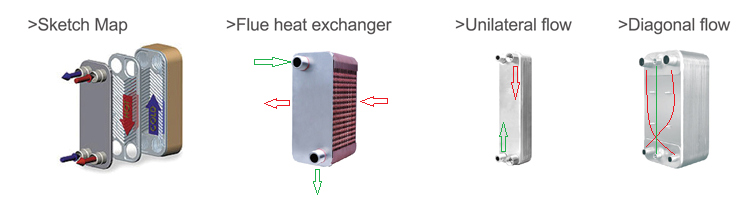

Brazed plate heat exchanger Fluid Flow principle

The basic flow principle in GHE brazed heat exchanger is parallel(except dual system BPHE)and current flow,this design make easier for installation

1) Flow principle in brazed plate heat exchanger Evaporator

In brazed plate heat exchanger,two media flow always in opposite direction,it is called current flow.the two phase refrigerant (vapor+liquid)enters the bottom left of the heat exchanger with a vapor quality depending on the operating condition of the application.Evaporation of the liquid phase takes place inside the channels and some degrees of superheat are always requested.

2) Flow principle in brazed plate heat exchanger Condenser

Same components as for the evaporator.the hot refrigerant enters at the top left of the heat exchanger and starts to condense on the surface of the channel until fully condensed ,sub cooling also requested .

3) Multipass Design brazed plate heat exchanger

The heat exchanger can be designed as a multipass until according to customers’ need.different connections location and type &size.customer specific design are available request.

4) Dual system brazed heat exchanger design

What is dual system?the dual circuit means two refrigerant flows and one water flow.the design is diagonal flow design,that means the brazed plate heat exchanger can be connected with two independent refrigerant circuits.this design can make sure each refrigerant circuit is in contact with the entire water flow.the main advantage is that although when only compressor running still can maximize the water cooling performance .

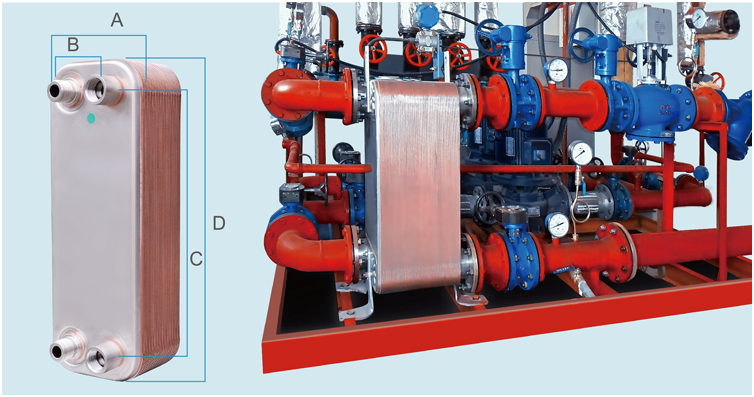

Brazed Plate Heat Exchanger Specification

Model | A (mm) | B (mm) | C (mm) | D (mm) | thickness (mm) | weight (mm) | Stagnant fluid volume (L) | Design pressure (Mpa) | Max fluid (L) |

GL014 | 76 | 42 | 172 | 206 | 9+2.3N | 0.6+0.056N | 0.010(N-2) | 1/3/4.5 | 8m3/h |

GL018 | 95 | 50 | 165 | 210 | 9+3.1N | 0.3+0.06N | 0.010(N-2) | 1 | 8m3/h |

GL020B | 78 | 42 | 282 | 318 | 9+2.3N | 0.9+0.088N | 0.018(N-2) | 3/4.5 | 8m3/h |

GL026 | 111 | 50 | 250 | 310 | 10+2.36N | 1.3+0.12N | 0.025(N-2) | 3/4.5 | 18m3/h |

GL030 | 124 | 70 | 250 | 304 | 13+2.4N | 2.2+0.146N | 0.032(N-2) | 3/4.5 | 18m3/h |

GL052A | 111 | 50 | 466 | 525 | 10+2.35N | 1.9+0.215N | 0.047(N-2) | 3/4.5 | 18m3/h |

GL052B | 111 | 50 | 466 | 525 | 10+2.35N | 1.9+0.213N | 0.047(N-2) | 3/4.5 | 18m3/h |

GL062B | 119 | 63 | 470 | 526 | 10+2.35N | 2.4+0.223N | 0.051(N-2) | 3/4.5 | 18m3/h |

GL095A | 191 | 92 | 519 | 616 | 11+2.76N | 6+0.415N | 0.125(N-2) | 3/4.5 | 42m3/h |

GL095B | 191 | 92 | 519 | 616 | 11+2.76N | 6+0.413N | 0.125(N-2) | 3/4.5 | 42m3/h |

GL0120A | 246 | 174 | 456 | 528 | 13+2.36N | 7+0.472N | 0.98(N-2) | 3/4.5 | 42m3/h |

GL0120B | 246 | 174 | 456 | 528 | 13+2.36N | 7+0.472N | 0.98 (N-2) | 3/4.5 | 42m3/h |

GL0200A | 321 | 188 | 603 | 738 | 9+1.58N | 13+0.74N | 0.22(N-2) | 1.5/2.1/3 | 100m3/h |

GL0200B | 321 | 188 | 603 | 738 | 13+2.7N | 13+0.73N | 0.22(N-2) | 1.5/2.1/3 | 100m3/h |

Notes:

N* is plate number

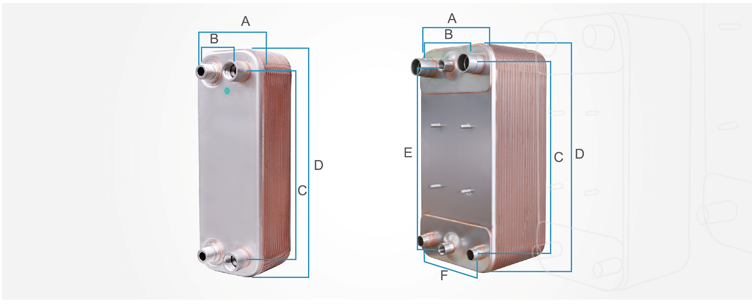

High efficiency heat exchanger

Our GL020, GL062 series, GL0130, GL0250 are specifically developed for R410A refrigerant, which is ideal alternative of R22. R410A efficient heat exchanger is not only resistant to high pressure, but also with less refrigerant to achieve the same cooling effect. GL020 and GL062 are unilateral flow. GL0130 and GL0250 are diagonal flow. They can work from the power range of 1KW to 250KW

Model | A (mm) | B (mm) | C (mm) | D (mm) | Thickness (mm) | Weight (mm) | Stagnant fluid volume (L) | Design pressure (Mpa) | Max fluid (L) |

GL020A | 86 | 40 | 269 | 315 | 9+1.58N | 1+0.084N | 0.018(N-2) | 3/4.5 | 8m3/h |

GL062A | 119 | 63 | 470 | 526 | 10+2.35N | 2.4+0.225N | 0.051(N-2) | 3/4.5 | 18m3/h |

Dual System*

Model | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | Thickness (mm) | Weight (mm) | Stagnant fluid volume (L) | Design pressure (Mpa) | Max fluid (L) |

GL0130 | 247 | 161 | 495 | 414 | 369 | 172 | 10+2.15N | 4+0.424N | 0.080(N-2) | 3/4.5 | 42m3/h |

GL0250 | 322 | 205.2 | 739 | 631.7 | 568 | 224.4 | 13+2.7N | 16+0.711N | 0.22(N-2) | 3/4.5 | 100m3/h |

Notes:

N* is plate number

Get Price And Support

Please leave your telephone number or mobile phone nubmer for emergency contact, in case we can not reach you by mail.

- 2022-05-30干式管壳式蒸发器的优缺点

- 2022-01-10可用的垫片式板换热器好在这里,你可别错过

- 2021-12-25蒸汽换热用板式换热器的类型和使用特点

- 2021-01-07板式热交换器更换垫圈应该用什么胶水

- 2020-09-05列管冷凝器的管外装置及循环水的运用